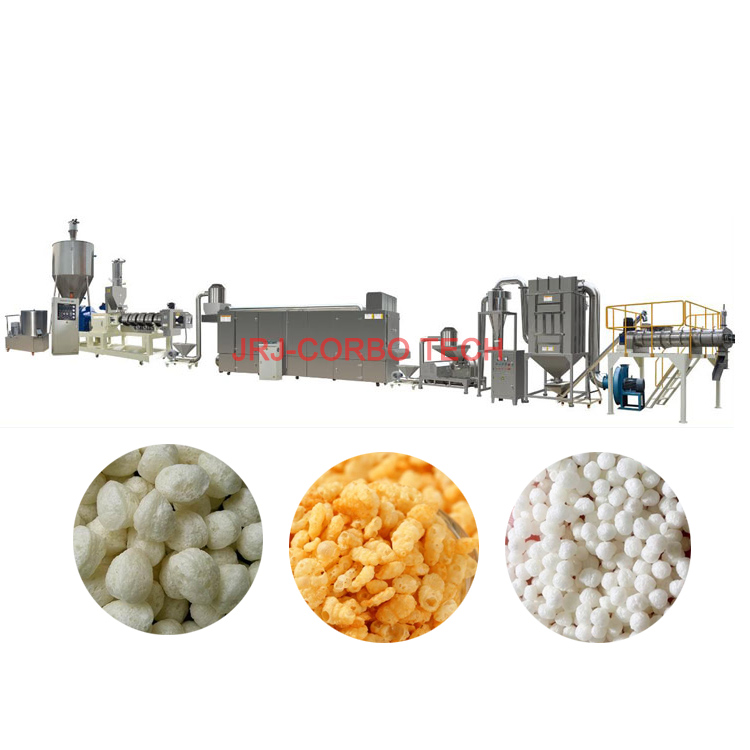

starch, tapioca starch etc as main materials, through extruding treatment process, to produce multi-functional and

high-valuable modified starch, Pre-gelatinization Starch or Denatured Starch. Its Double Screw Extruder is special

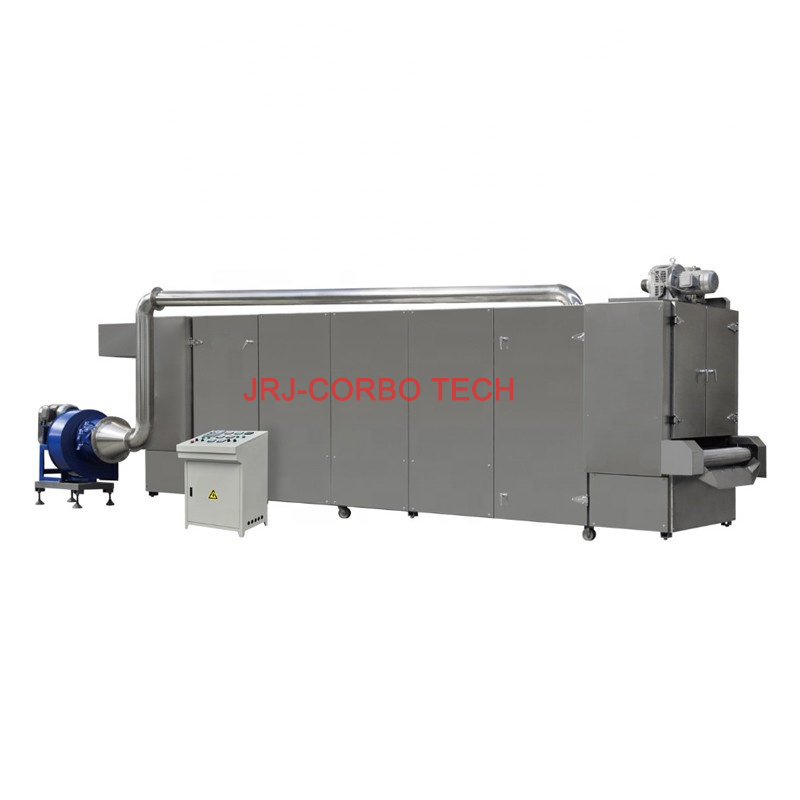

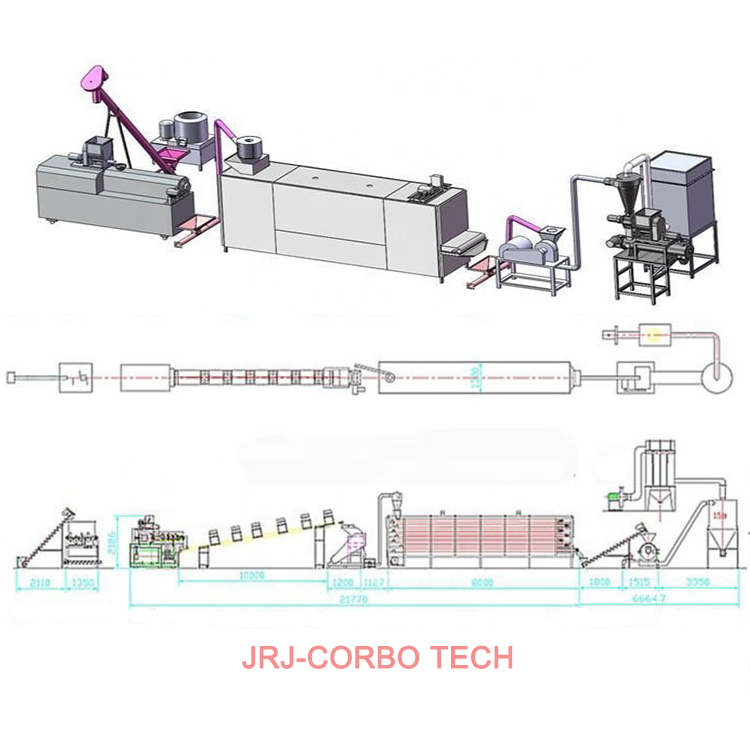

designed, consists of 6 systems: feeding system, extruding system, cutting system, heating system, conveying

system and cooling system, its barrels and screws structure can easily realize the function of changing the

properties of the starch. Modified Starch can be used in many fields like Textile, Food, paper making, building

material, casting, oil drilling and so on.

1. Raw Materials: natural starch, like corn starch, cassava starch, tapioca starch etc

2. Products: Modified Starch.

3. Capacity: 120-150 KG/H,200-250 KG/H,400-500 KG/H

4. Flow Chart: Mixing —Extrusion —Baking —Grinding

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage

of different countries.

6. Machines Materials: All the machines are made by food grade stainless steel.

|

Model |

Installed Power |

Power Consumption |

Output |

Size(L×W× H) |

|

PL100 |

63kw |

45kw |

150kg/h |

20000x1200x2200mm |

|

PL200 |

145kw |

87kw |

200-250kg/h |

21000x1500x2200mm |

|

PL400 |

153kw |

92kw |

400-500kg/h |

31000x3500x4300mm |

Cobro Tech

Cobro Tech